Why is there a difference in color in one-piece inductors?9

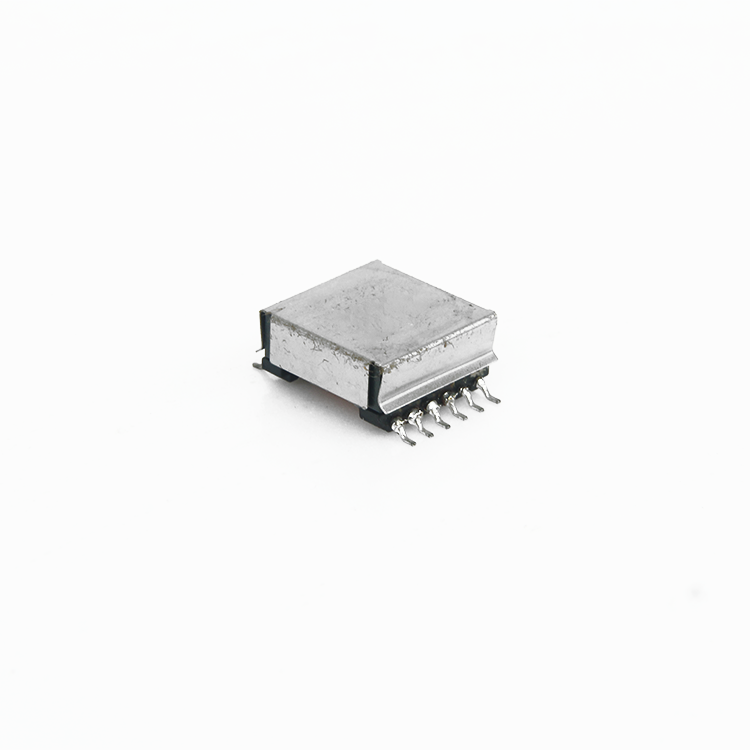

Onepiece molded inductors are also called compression molded inductors. There are still some customers who don’t know their names, but it’s not impossible to call them square inductors by looking at their appearance. The onepiece inductor uses the overall design of SMD. The magnetic system embeds the coil itself in the metal material with a magnetic powderlike internal structure of aluminum diecasting. The SMD pin is the leadout pin of the winding itself and is immediately formed on the surface of the seat. Therefore, the onepiece inductors we see are boxy and very neat. This design not only improves product quality, but also is not easy to damage the inductor. Recently, a customer followed up, why the color of the onepiece inductor is different, there are silver white and dark gray, what is the difference between the two?

In fact, the color of the onepiece inductor is just to spray a layer of silver white or dark gray or even black paint on the surface, the purpose is to prevent the metal from rusting. As for why the colors are different, it is actually because inductor manufacturers customize inductors of different colors according to the needs of enterprises. In fact, there is no difference in other characteristics between the onepiece inductors of different colors, it is only based on the requirements of Party A or the manufacturer's investigation of its spraying. In addition, metal powder powder is also divided into alloy products and vermicelli raw materials. Alloy powder has a good antirust effect and high inductance, but its current characteristics are poor. Fan current characteristics are more suitable, but the antirust effect is poor Its sensitivity is low and at the same time it needs to be sprayed, and surface modifiers can be used to improve the antirust effect. Therefore, the integrally formed inductors with surface spraying are generally processed from vermicelli raw materials.

Article classification:

Company news

|